Autonomous Haulage Mining

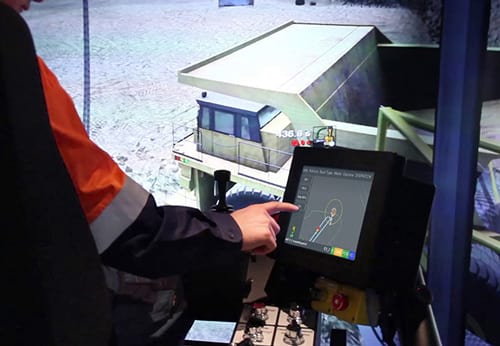

Immersive Technologies are the only provider who have successfully developed and implemented simulation-based training solutions for in-field roles within an autonomous haulage environment.

5% Improvement in Autonomous Truck Cycle time

7% Improvement in Autonomous Truck Interchange time

20% Improvement in Autonomous Truck Queue time

Automation within the mining industry is transforming the nature of work performed by people both within the mine site and in the back office. Often, the importance of the role of the person working within autonomous operations is underestimated, particularly their ability to compensate for the unexpected. This underestimation can dilute or negate the benefits achievable from running an autonomous operation. Therefore, selecting the right people, effective training and upskilling strategies are key to ensuring a highly efficient autonomous operation.

Why is it important to select the right people to operate the right equipment?

Human errors and underperformance within an autonomous haulage environment will significantly impact operational efficiency and production. This is especially true for critical roles such as loading equipment operators who play a significant role in realizing the benefits of autonomous system implementation.

Why is it important to choose an effective training strategy upfront?

In-effective training approaches will lead to increased human errors due to poor understanding and low knowledge retention. This has significant impact on mine profitability risking safety, machine damage and productivity, along with limiting the speed of deployment significantly.