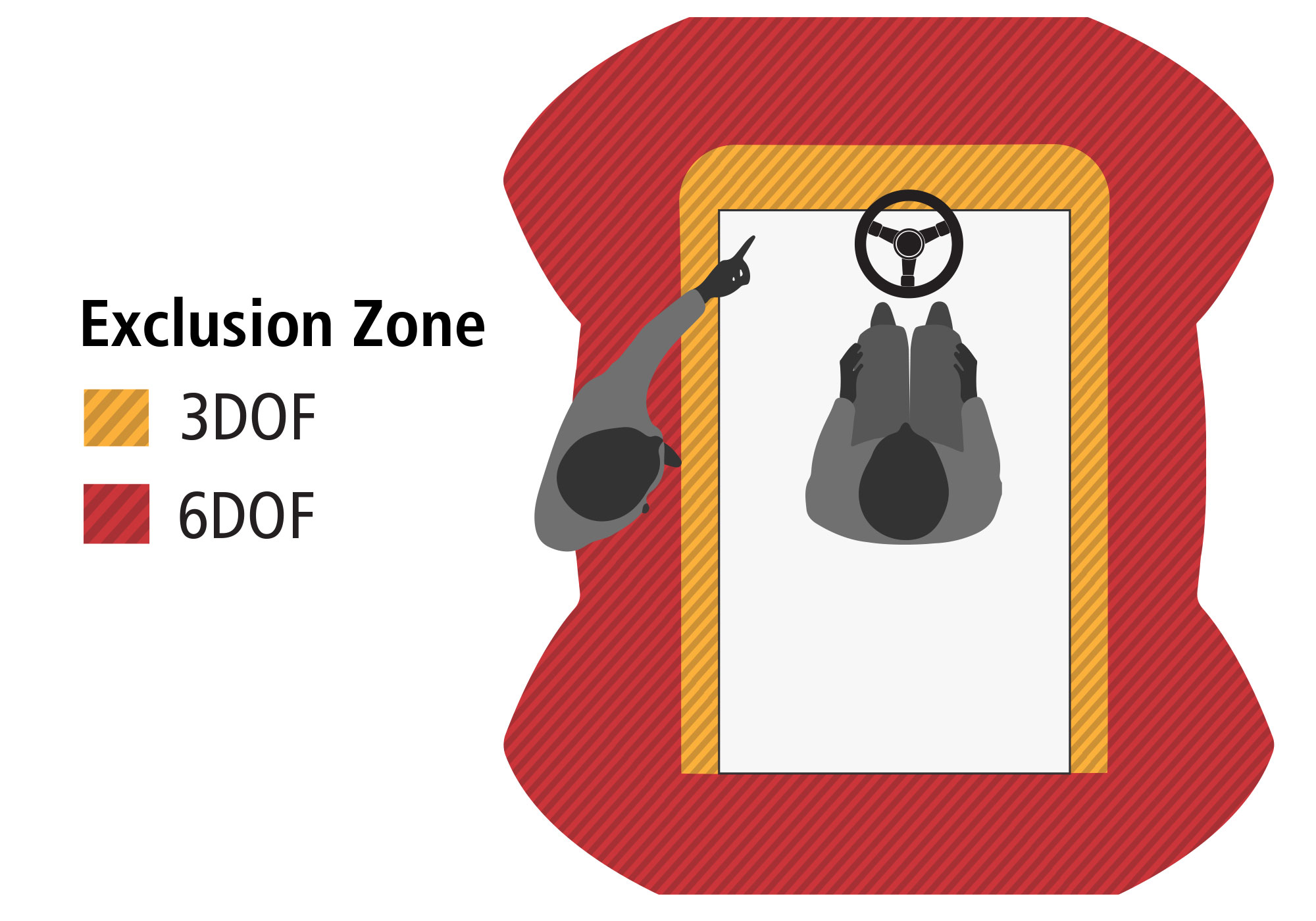

For the most effective training and skills transfer, experts agree that a simulator needs visual, auditory and motion accuracy. Motion provides life-like cues to the operator, maintains interest for longer and increases experienced operator acceptance of simulation training. Immersive Technologies analyzed and selected a 3DOF motion platform as the most suitable system for the simulation of mining and earth-moving machines based on its high level of safety, training effectiveness and reliability.

Login

Login